Offset Printing Mechanism – The Two Different Approaches

- By Eliza Smuel

- •

- 03 Mar, 2017

- •

First of all, I will explain a little of the offset printers background that why it is called offset and what are those mechanism because of which the term offset is implemented. In printing jobs, what need to be printed on the paper is printed on a metal sheet known as plate. Several of the readers may think of the plate and paper are in continuous contact with each other for printing job to be done, but none of them are thinking on the right direction.

Then how the image on the plate is printed on the paper? That’s because there involve multiple cylinders and rollers which indirectly connect plate and paper. This way there is no wearing and tearing of the plate thus results prolonging the plate’s life by protecting its continuous contact with the paper. The term offset is therefore derived from this mechanism.

Offset printing Dubai is the most common technology for all of the mass production of newspaper, magazines and stationary products. The main cause of offset printer’s popularity is quality image prints on affordable price, therefore this cost effective feature results in high demand of machines for printing press solutions in Dubai, America, KSA and the rest of developing countries.Basic Principles of Offset Printing:

Water and oil do not make a homogeneous mixture upon mixing together. Further exploring the concept of oil and water and their mixture is just concern with the metal plate that has the image of document to be printed. There locate two portions on the plate, one is image portion that have to be printed on the paper, the other is non-image portion which doesn’t. The whole plate is wetted with water and then dampened in oil based ink.

The actual principles of science do the real trick here. All the image portion repel water and pick up ink and the rest of the non-image portion stay with water. After picking up ink, the image is transferred to a rubber cylinder or roller. After continuous transfer from cylinder to cylinder the image is allowed for printing on the media that might be a paper.

Offset Types:

There are two different types of offset printing which are:

Web-fed Offset Printers:

When the printing requirements of impressions are more than 10-20 thousand, this type of machine is used because these are specially designed for high volume publications. In case of web-fed offset, a continuous roll of media (paper in this case) is fed into machine and once the print job is done, the paper is cut into pieces and separated. Newspaper publication is carried out mostly with web-fed offset printers.

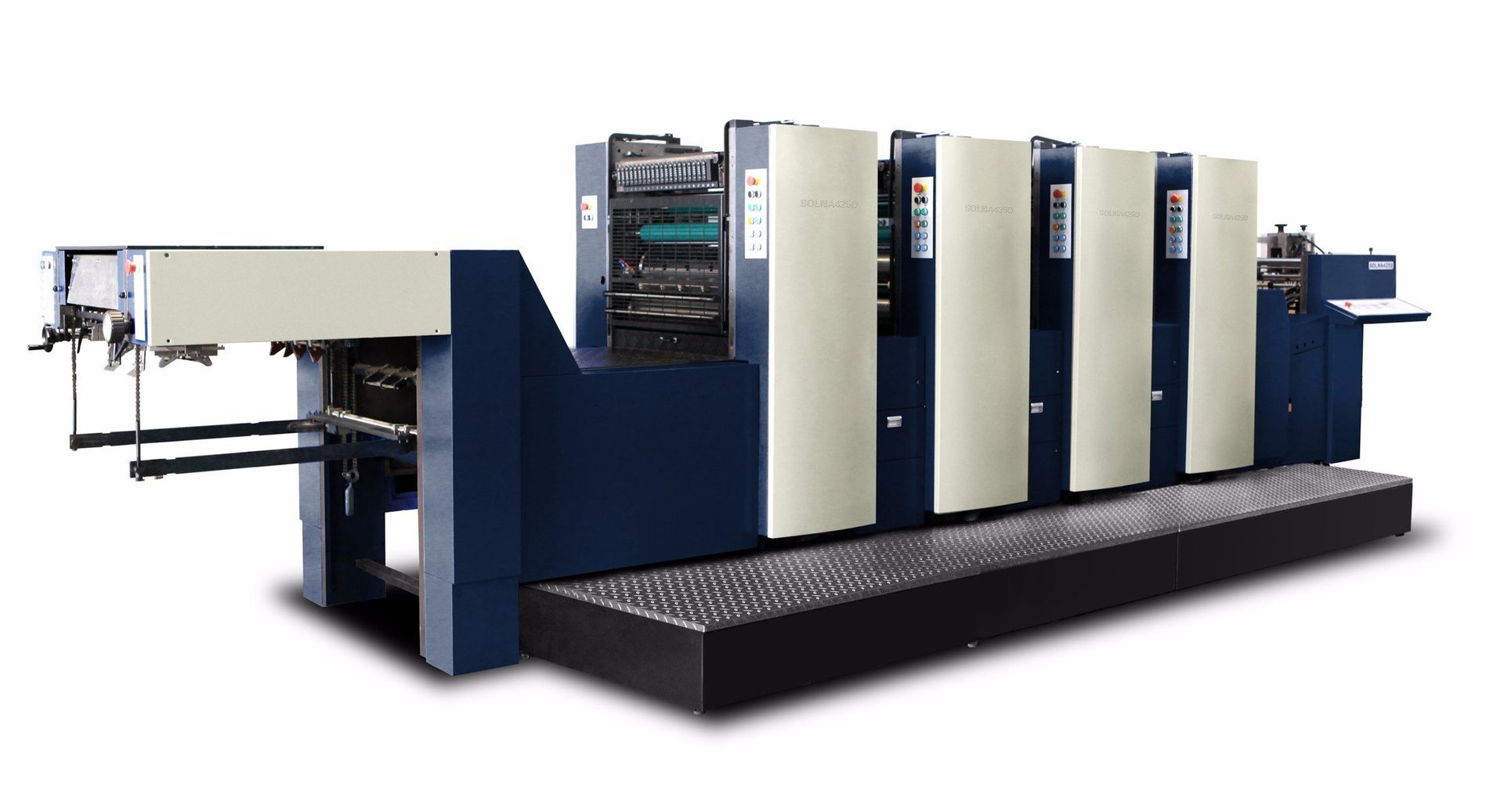

Sheet-fed Offset Printers:

Mostly used for limited edition of books, plastic and cardboard printing, the use of sheet-fed offset print machines use paper that is cut into desired size and then fed into the machine. The use of single individual sheets for each print makes it easy to maintain instead of using a roll of paper.

Speedy prints, high amount of impressions per hour and the rate of paper wastage are the main differences between these machines. Web-fed offset machines are the perfect solution for finishing the print job quickly. There is no need of inserting individual sheets manually to feed and so the whole role of paper fed accelerate the rate of prints.

Web-fed offset printers are able to print up to 40,000 of impressions in a given time of an hour while sheet-fed offset printers can only perform up to 14,000 impressions per hour. Thus the output rate of web-fed offset machines is much greater than the later one.

However, for the reason of paper wastage, offset printing Dubai press solutions suggest sheet-fed offset print machines for medium sized production because the rate of paper waste is minimal in case of these machines as compare to web-offset. However, for mass production and high quantity of publication, the web-fed offset print technology is a better option.